Introduction

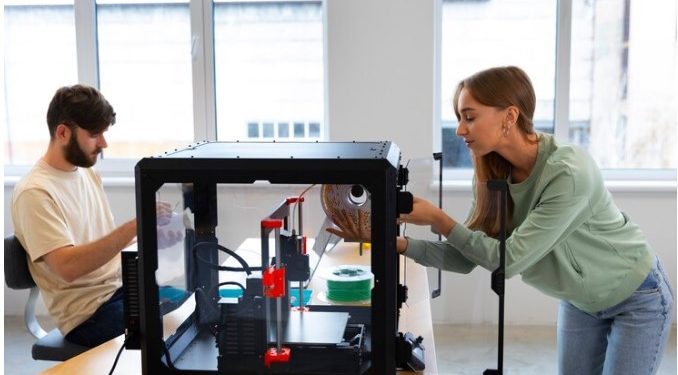

In the ever-evolving world of technology, 3D printing stands out as one of the most transformative innovations of our time. This groundbreaking technology, also known as additive manufacturing, is revolutionizing how products are designed, prototyped, and manufactured across various industries. But what exactly is 3D printing, and how does it work? Let’s delve into the fascinating world of 3D printing and explore how this incredible technology is changing the way we create and innovate.

Understanding 3D Printing

3D printing is a process of creating three-dimensional objects from a digital file by adding material layer by layer. Unlike traditional manufacturing methods, which often involve cutting or molding material, 3D printing builds objects layer by layer, hence the term “additive manufacturing.” This layer-by-layer approach allows for creating highly complex shapes that would be impossible to achieve with traditional methods.

How Does 3D Printing Work?

- Designing the Model

Every 3D printing project starts with a digital design. This design is usually created using Computer-Aided Design (CAD) software or 3D scanning. Once the model is complete, it’s converted into a file format that the 3D printer can read, typically STL or OBJ. - Slicing the Model

The digital model is then “sliced” into thin layers using slicing software. This software also generates the instructions (G-code) for the 3D printer, detailing how each layer should be printed. - Printing the Object

The 3D printer receives the instructions and begins printing layer by layer. Different 3D printing technologies use different methods to deposit and solidify the material, ranging from melting plastics to curing resins with UV light. - Post-Processing

After printing is complete, the object may require post-processing, such as removing support structures, sanding, or painting, to achieve the desired finish.

Common 3D Printing Technologies

- Fused Deposition Modeling (FDM)

FDM is one of the most popular 3D printing methods. It involves melting thermoplastic filament and extruding it layer by layer to build an object. This technique is widely used for prototyping and creating functional parts due to its affordability and versatility. - Stereolithography (SLA)

SLA uses a UV laser to cure liquid resin layer by layer. This technology is known for producing highly detailed objects with smooth surface finishes, making it ideal for jewelry, dental models, and intricate prototypes. - Selective Laser Sintering (SLS)

SLS employs a high-powered laser to fuse powdered materials, such as nylon or metals, layer by layer. This method is excellent for creating durable and complex parts without the need for support structures. - PolyJet Printing

PolyJet printers jet layers of liquid photopolymer onto a build platform and cure them with UV light. This technology can produce objects with multiple colors and materials, making it perfect for realistic prototypes and medical models. - Digital Light Processing (DLP)

Similar to SLA, DLP uses a digital light projector to cure liquid resin. It’s known for its speed and ability to produce fine details.

Applications of 3D Printing

- Rapid 3D Printing Prototyping

3D printing has revolutionized prototyping by allowing designers to quickly and affordably create and test prototypes before committing to full-scale production. - Medical and Dental

Custom prosthetics, implants, and dental models are now being created with incredible precision thanks to 3D printing. This technology allows for personalized medical solutions that improve patient outcomes. - Automotive and Aerospace

Automotive and aerospace industries use 3D printing to produce lightweight, complex parts that reduce weight and improve fuel efficiency. - Consumer Products

From custom jewelry to fashion accessories, 3D printing is empowering designers to create unique, personalized consumer products. - Architecture and Construction

Architects use 3D printing to produce detailed scale models of their designs, while the construction industry is experimenting with 3D printed buildings and structures.

Advantages of 3D Printing

- Design Flexibility

3D printing allows designers to create highly complex and intricate shapes that would be impossible with traditional manufacturing. - Reduced Waste

Traditional manufacturing often involves cutting away excess material, leading to waste. In contrast, 3D printing uses only the necessary amount of material. - Cost-Efficiency

For small production runs and prototypes, 3D printing can be much more cost-effective than traditional manufacturing. - Customization

3D printing makes it easy to customize products to individual specifications, which is particularly useful in medical applications. - Rapid Production

By cutting down on tooling and setup times, 3D printing significantly speeds up the production process.

Conclusion

3D printing is more than just a trend; it’s a technological revolution that’s transforming industries across the globe. By understanding the basics of 3D printing and its applications, businesses and individuals can harness its power to innovate, create, and stay ahead in an increasingly competitive world.

Call to Action

Are you ready to explore the possibilities of 3D printing for your next project? Find the perfect 3D printing freelancer on 3DJobber today, and bring your creative vision to life with the latest in additive manufacturing technology. Embrace the future of design and production—start your 3D printing journey now!